A new era of proactive warehouse automation

Proactive warehouse automation, enhanced with an in-built digital twin, is becoming essential for companies aiming to meet modern supply chain demands. The need for short delivery times, flexibility in order size, and better inventory control are the primary drivers for adopting warehouse automation. To compete in the market, producers must be able to respond efficiently to customer demands. Pesmel Material Flow How® solution is a fully automated high-bay and logistics concept designed to meet these challenges.

Key technology: The Pesmel Material Flow WMS and WMS Digital Twin

Material Flow How® concept provides integrated in-mill logistics to enable a seamless connection between production and dispatching with full information and material flows. The technical advantage of the concept is its high level of warehouse automation, overall performance and flexibility. The system is managed by the Material Flow WMS (Warehouse Management System), which controls the flow of products and optimises storage and logistics functions. This enables the efficient handling and collection of complex orders with hundreds of different SKUs (Stock Keeping Units) on time.

A key component of the Material Flow WMS is the WMS Digital Twin, which is a software solution that simulates a real-world warehouse setup in a digital environment. Unlike traditional models that rely on calculations, this digital twin is in-built into the WMS, allowing for accurate simulations based on real-time data. The digital twin provides valuable information for day-to-day decision-making, updates, and service operations, and it supports operations across the mill’s entire lifecycle. Its models and estimations enable informed and optimised operations from system deployment through active operations.

The digital twin’s role across the operational lifecycle

The WMS Digital Twin performs several key tasks throughout the life of the material handling solution:

Concept Validation

The implementation process begins by building a simulation model of the customer’s warehouse to analyse material flows and identify potential bottlenecks. This provides concept validation with 3D-visualisation and simulations to identify the optimal logistic solution. The concept is modelled in the WMS Digital Twin to ensure 100% accuracy. This systematic approach allows for pre-construction testing and verification of large and complex configurations. The detailed information from the simulation notifies the engineering and design of the logistics concept, including mechanical, electrical, PLC, and ICT components.

Software Development and Virtual Commissioning

In projects with significant capital expenditure (CAPEX) time is of the essence. Integrating digital twin technology from the beginning drastically reduces start-up costs and time while improving efficiency. Data from inputs to shipping is fed into the WMS Digital Twin from the start, and its analysis helps to illustrate an optimised physical configuration for the warehouse.

The digital twin allows the facility to become virtually operational even before it is built. This makes implementing large warehouse projects fast and reliable. Unlike traditional setups that may take months to streamline after start-up, optimisation is performed during the implementation phase with the digital twin.

After the facility is operational, the virtual environment remains available, allowing for safe testing and optimisation without interrupting production. A key feature is the ability to run the model at a much higher speed than in real life, simulating a ten-day operation in just a few hours.

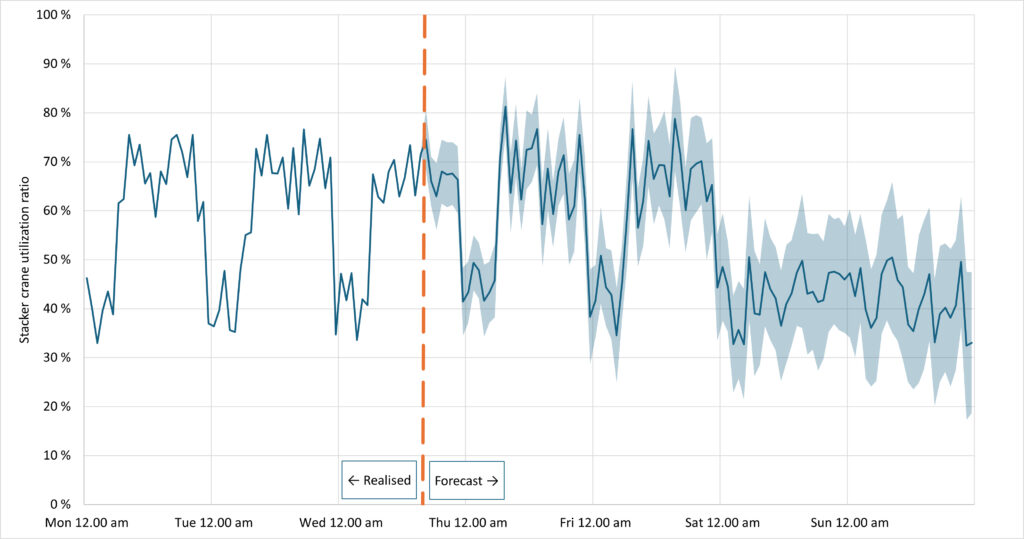

Forecasting and Decision-Making Parallel to Production

While many applications of digital twin technology are limited to simulations used for the initial design and planning of warehousing solutions, the full potential of the WMS Digital Twin is realised when it operates in parallel with a running mill. By using real-time data, it enhances predictability and optimises material flow performance on a day-to-day basis. The key role of a digital twin integrated into a live environment is to support the development of operational efficiency through accurate predictions and simulations.

The WMS Digital Twin provides a safe, simulated digital environment to model outcomes, which supports informed decision-making with minimal risk to the ongoing process. All results generated by the digital twin can be accessed through the WMS user interface, enabling warehouse operators, maintenance personnel, or production planners to make necessary decisions regarding their daily work and operations.

The WMS Digital Twin enables advanced planning and trials. For instance, it allows for simulation-based planning of stock optimisation. It can be used to accurately model scenarios to optimise the smooth flow of products through the warehouse and determine the required minimum volume of existing stock for all various product variants in inventory. The stock optimisation data can include information such as the warehouse fill ratio, fill percentage, or the number of empty storage channels.

Additionally, it can accurately predict dispatching times. By setting specific limit values, users can receive notifications of needed reactions well in advance. The statistical probability of shipment cancellations or the appearance of unplanned shipments can also be modelled to predict possible material shortages or warehouse capacity issues.

Proactive Service and Future Updates

The digital twin enables accurate modelling and planning of scheduled maintenance. Simulations that consider upcoming customer deliveries and production plans can identify the optimal time to take specific stacker cranes offline for preventative maintenance, ensuring the mill can still fulfil anticipated orders. The digital twin can also simulate how the system will behave during maintenance breaks and how operations will return to normal afterwards. This proactive support is crucial for maintaining continuous operations and efficiency.