Pulp & paper industry

Find out more about our Material Flow How® concept covering the processes from material handling to high-bay storage and dispatching for paper rolls and pulp bales.

Click the links below to find out more about our Material Flow How® concept for the pulp & paper industry.

Pesmel’s Material Flow How® concept is designed to optimize a mill’s intralogistics and make the supply chain more efficient. Our concept for pulp and paper industry includes automated handling and high-bay warehousing integrated with our proprietary warehouse management system (WMS) software.

The main idea of the concept is having automated warehouses in the mill area capable of handling all material flows from the production lines. With centralized warehousing operations overall logistics is simplified, and the need for satellite or external warehouses is removed. Automated high-bay warehouses offer full integration with logistics processes and enables a truly streamlined supply chain.

Solution engineering

Pesmel delivers individual solutions engineered to improve customers’ material flows. As a total system supplier, we take overall responsibility for the project from pre-engineering to handover. Planning starts with defining the needs of a functional layout, material flows between processes, requirements for the finishing area, and alternative routings for exceptional situations.

We build a simulation model to design, develop, optimize, and validate our logistics systems. The model acts as a guidance for implementing a fully functional and optimized system. It enables pre-construction testing and verification of large and complex systems.

The simulation process creates a digital twin, which is a virtual representation that serves as the digital counterpart of a physical process. Our digital twin is proven to be a usable tool in commissioning and development of our customers’ material flow solution.

A digital twin is also used in daily operations such as continuous optimization of automated storage, support for operator’s decision-making, and estimation of near future occurrences. It also plays an important role in planning and executing aftersales operations including data collection of equipment usage, preventive maintenance, and virtual testing of software updates.

Handling

Pesmel is a one-stop-shop for all in-mill logistics needs at pulp and paper mills and converting plants. Our solutions cover the conveying, and storing concepts needed to rolls and bales across the entire supply chain.

Conveying is the connecting link between production, warehouse, and distribution functions. Automated interoperability of these functions achieves efficient product flow without bottlenecks. The key to efficient in-mill logistics is a well-designed mill layout with smooth interfaces between processes. Smart layout design reduces the number of conveyors and avoids complex, inefficient conveyor systems.

All systems are engineered based on an understanding of how the products – whether paper rolls or pulp bales – need to be handled. Intelligent and fully automated functions ensure smooth and damage-free material flow everywhere between production and shipping. Our range of material handling includes all types of conveyors with special equipment and systems for sorting and loading.

Automated warehousing

Optimizing warehouse operations lays the foundation for improvements across the entire supply chain. Modern warehouses are automated and can be fully integrated into the logistics process, increasing efficiency, reducing costs, and allowing simplified material flow.

One of the biggest plus points of automated warehousing is its contribution to automation and data sharing, making it more flexible, agile, and transparent. Instructions, reports, and other data can be shared and utilized for improved management and control. Both mill production and warehouse operations benefit, as inventory control is automated and handling and storing of different stock keeping units (SKUs) is efficient.

Our TransRoll™ and TransBale™ high-bay deep lane storages, with their sizeable sorting abilities, are especially well-suited for large units and volumes or for production involving a considerable number of SKUs. The high-bay rack storage structure uses one-third of the space compared to a traditional warehouse, which makes it a superb solution for dense mill areas. Storage solutions can be adapted to a new or existing facilities.

Dispatching

The transportation of goods can take less than 50 percent of the total time of the supply chain process, and opportunities to reduce this time further are limited. This means that the biggest potential for time savings in the supply chain occurs at turnaround points where goods are loaded, unloaded, and stored.

The efficiency of the mill’s entire supply chain can be greatly improved by using a smart system for conveying, storage, and retrieval, as well as in loading and unloading operations. Turnaround times have been cut to one-third using Pesmel’s solution, meaning that the truck loading process takes 20-30 minutes, and around three hours for loading trains. This means that trucks spend significantly less time waiting, they can deliver your products quicker, and trains are utilized more effectively and efficiently.

Control (WMS)

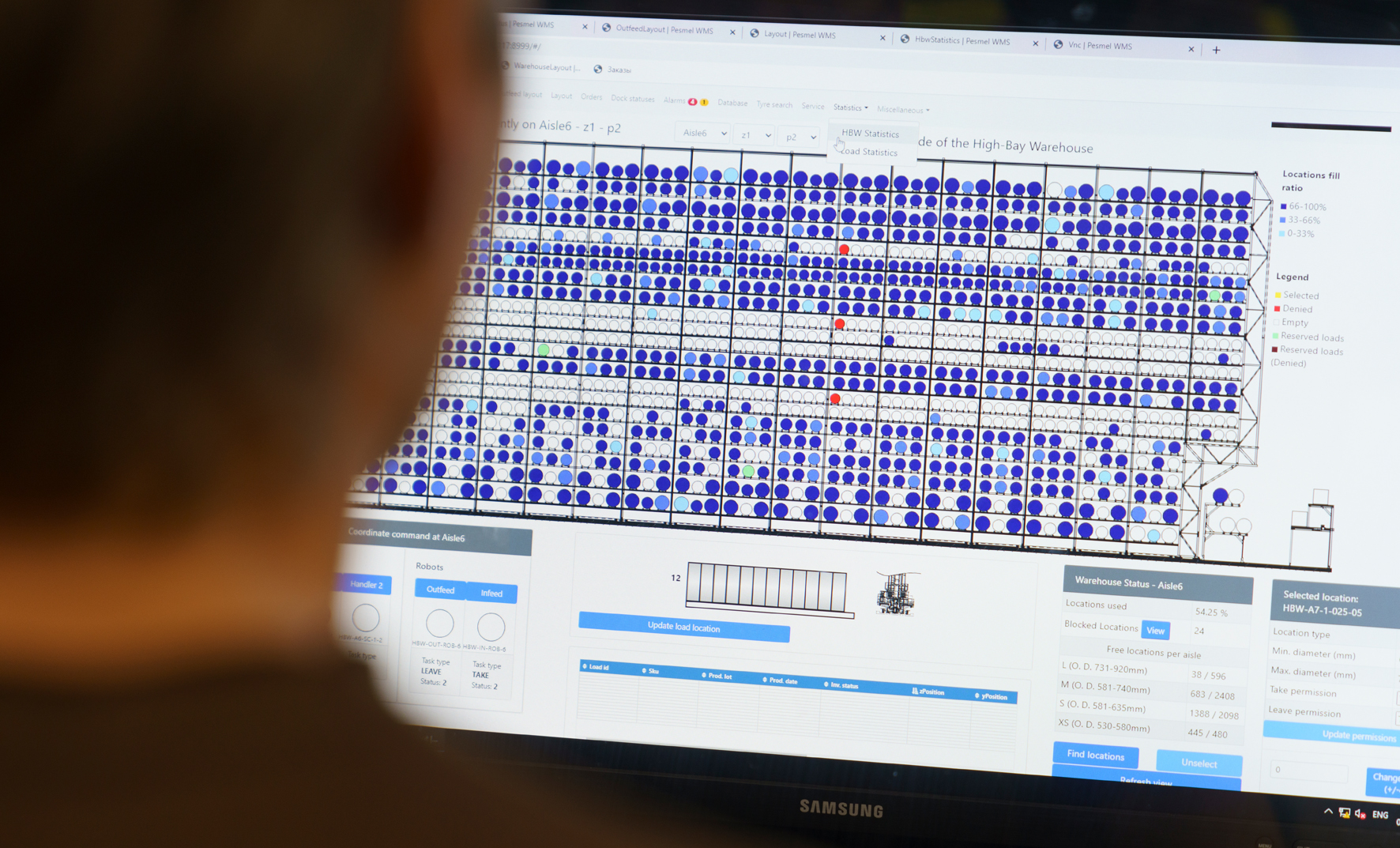

Pesmel’s Material Flow How® concept includes equipment integration, material flow management throughout the entire mill, and information flow management. A control system enables integration of the various functions contained within the mill into one logistical entity.

Full material handling control means zero damage and no lost products or delivery errors. The entire system – logistics, storage, and packaging – is managed by a centralized control system which tracks and tasks the products from arrival to departure. The real-time inventory feature significantly supports production planning – a critical area in terms of cost savings.

A state-of-the-art mill needs a modern control structure. Our system integrates all levels of production and logistics control, from electrification to automation, monitoring, material flow planning and management and logistics, into one full chain using a comprehensive and user-friendly platform.

Material library

Browse through additional materials to learn more about our material flow solutions for pulp and paper industry.

Brochures

Automated intralogistics for Pulp and Paper

Published on: 03.04.2024

Customer Magazines

Material FlowHow Paper 2024

Published on: 03.04.2024

Material FlowHow Paper 2022

Published on: 03.06.2022

Material FlowHow Paper 2020

Published on: 07.07.2020

Videos

Material Flow How® offering for pulp & paper industry

Published on: 30.01.2025

Automated Pulp warehouse for ports

Published on: 30.01.2025

Pesmel high-bay warehousing for pulp and paper industry

Published on: 13.06.2022

Pesmel TransRoll, case Saica Paper

Published on: 03.06.2021

Distribution center for pulp bales

Published on: 02.02.2017

References. Pesmel solutions for pulp & paper.

Find out how our Material Flow How® concept is delivering improved packaging, handling, storage and logistics performance to pulp & paper mills around the world. With over 40 years of experience and more than 400 successful deliveries, our solutions are truly tried and tested.

References. Pesmel solutions for pulp & paper.

Find out how our Material Flow How® concept is delivering improved packaging, handling, storage and logistics performance to pulp & paper mills around the world. With over 40 years of experience and more than 400 successful deliveries, our solutions are truly tried and tested.

Pulp & Paper industry contacts

Want to hear more about the benefits that our Material Flow How® concept could deliver to your pulp & paper business? Get in touch with your nearest Pesmel representative today.

Let's get connected.

If you are interested in finding out more, please, leave us your details and we will get in touch.